AGROS is your pride

Product

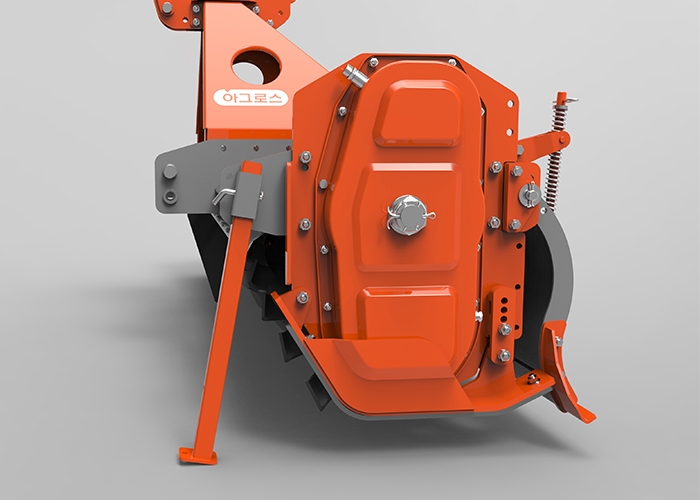

Rotary Tillers

The AGROS rotary tillers boast high durability thanks to their sturdy design,

and help with efficient soil cultivation through a variety of models.

Wide Type (for rice fields only)

Rotary Tillers

(AR6000SC)

The AR6000SC series can be mounted on tractors with 70~150

HP and is a wide type suitable for paddy field work.

This is a rotary tiller.

Using high-tensile steel, the blade shaft (BLADE SHAFT) boasts

exceptional strength and durability, and features a large-diameter

pipe design that excels in soil preparation and burying straw.

Specifications

| Model |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

Flanges (EA) |

Blades (EA) |

Speed (rpm) |

(hp) |

|

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AR6240SC | 2,360 | 1,160 | 915 | 2,355 | 100~130 | 9 | 54 | 156, 175, 196, 219 / 540rpm |

70~85 | 660 | 670 |

| AR6260SC | 2,880 | 1,230 | 940 | 2,660 | 10 | 60 | 85~100 | 710 | 800 | ||

| AR6280SC | 3,080 | 2,785 | 11 | 66 | 100~120 | 840 | |||||

| AR6300SC | 3,275 | 2,980 | 12 | 72 | 120~150 | 875 |

* These specifications may be changed without prior notice to improve performance and quality.

Product Features

-

Feature 01

Up to 80 HP (6240) and 150 HP (6260)

multi-speed gearboxes applied

(Oil gauge installed as standard) -

Feature 02

- - Spring tension and rolling type back cover

(Using high tensile steel plate) - - The rear cover adjustment bracket can be

moved and installed

- - Spring tension and rolling type back cover

-

Feature 03

Main deck with frame structure

with high-strength double BEAM -

Feature 04

- - Powerful special Geared side drive

of material - - Perfect gear fixation using special

grooved nuts

- - Powerful special Geared side drive

-

Feature 05

- - Blade with excellent low load and

soil fluidity Arrangement - - Applied a large-diameter pipe that excels

in burying straw

- - Blade with excellent low load and

-

Feature 06

- - Economical and convenient replacement

type Auxiliary skid - - Use of highly durable spring steel

- - Economical and convenient replacement

-

Feature 07

- - Special front mud splatter prevention

rubber plate with good material flexibility - - Detachable type for easy attachment

and detachment

- - Special front mud splatter prevention

-

Feature 08

Versatile with sturdy structure

and various mounting holes top master

Rotary tiller maintenance inspection and refueling items(AR6000SC)

▲ : Check

● : Replace

| Inspection Point | Oil Type | Oil Inspection Time | Volume | Instructions | |||

|---|---|---|---|---|---|---|---|

| Everyday | 50 Hours Everyday |

100 Hours Everyday |

200 Hours Everyday |

||||

| Gearbox | Gear Oil | ▲ | ▲ | ● | 8.0 | Check the oil level using the oil gauge, and replace or add oil as needed. | |

| Side Cover | Gear Oil | ▲ | ▲ | ● | 4.0 | If oil does not flow out when you open the inspection plug, add oil. If oil flows out, check the oil's color and foreign matter condition, and replace the oil if necessary. |

|

| Bearing Cover | Gear Oil | ▲ | ▲ | 0.2 | The oil level is adequate when it reaches the inspection plug. | ||

| Universal Joint | Grease | ▲ | ▲ | Grease Nipple Injection | |||

| Conclusion of Each Part |

▲ | ▲ | Check the attachment status of the top master’s plow blade and the plow shaft. |

||||

| Blade | ▲ | ▲ | Inspect bolts and nuts for any damage or deformation. | ||||

※ After the initial 50 hours of use, replace all areas where gear oil is injected.

※ When replacing oil, dispose of waste at a designated, authorized waste disposal facility.

-

Contact Us

031.8057.9311Our Product Online Quote Inquiry

- Fax. 031-8057-9313

- agros@agros.co.kr

-

Business Hours :

09:00~18:00

Lunch Time :

12:30~13:30

※ Closed on weekends

and public holidays

- Download

- Youtube

- TOP