AGROS is your pride

Product

Rotary Tillers

The AGROS rotary tillers boast high durability thanks to their sturdy design,

and help with efficient soil cultivation through a variety of models.

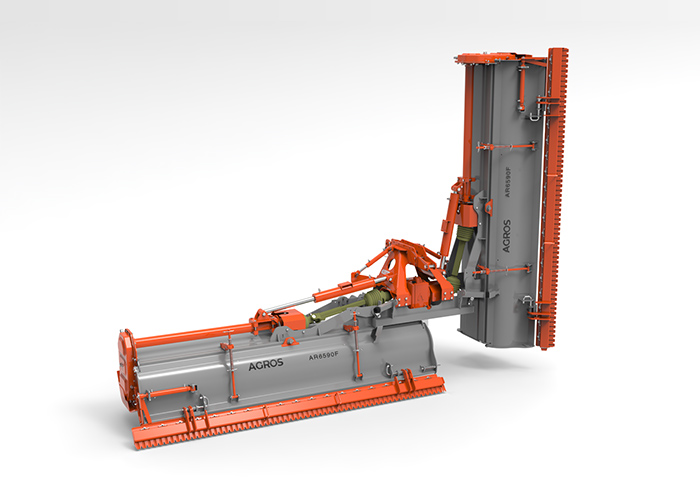

Folder (for rice fields only)

Rotary Tillers

(AR6000F)

AGROS Folder can perfectly perform both

dry paddy rotary tiller work and dry paddy grading work.

Special anti-shake device to enable stable movement.

Detachable Equipped with a folding harrow,

safety and work completion are very high.

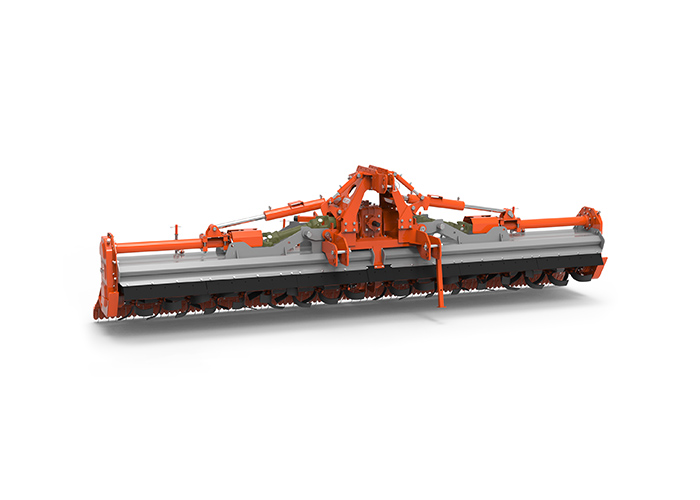

Specifications

| Model |

(mm) |

(mm) |

(mm) |

(mm) |

(mm) |

Flanges (EA) |

Blades (EA) |

Speed (rpm) |

(hp) |

|

(kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| AR6380F | 3,970 | 1,215 | 980 | 3,740 | 90~120 | 14 | 84 | 184 / 540rpm |

70~90 | 680 | 1,090 |

| AR6420F | 4,425 | 4,190 | 16 | 96 | 80~100 | 1,145 | |||||

| AR6460F | 4,850 | 1,270 | 1,040 | 4,575 | 18 | 108 | 194 / 540rpm |

100~110 | 770 | 1,440 | |

| AR6520F | 5,445 | 5,185 | 20 | 120 | 110~130 | 1,560 | |||||

| AR6590F | 6,145 | 5,875 | 22 | 132 | 130~150 | 1,660 |

* These specifications may be changed without prior notice to improve performance and quality.

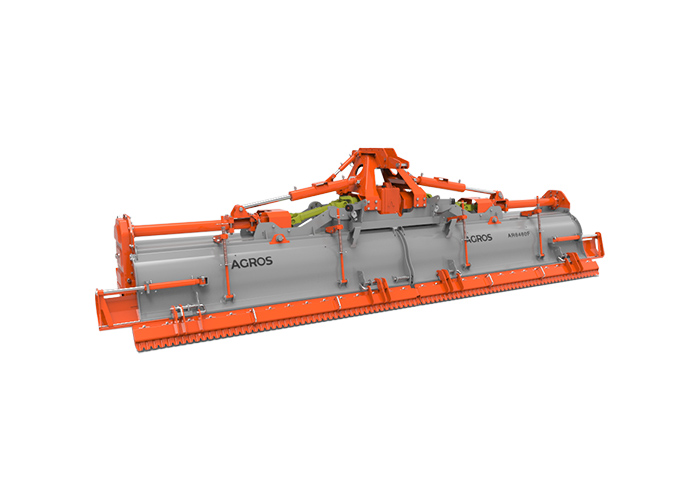

Product Features

-

Feature 01

Safety ensured during folding with

automatic hydraulic-operated lock cylinder

installation. -

Feature 02

Equipped with a 3-point hitch device

at the rear of the top master,

making it easy to attach accessories

like the harrow. -

Feature 03

High-strength rotary tiller blades installed,

providing excellent performance for both

dry paddy field tilling and non-paddy

field work. -

Feature 04

Hook-type harrow bracket for easy attachment

and detachment. -

Feature 05

Specially designed front flexible mud guard

made from a special material,

with standard installation (modular and

easily detachable). -

Feature 06

Standard installation of straw burial spring,

enabling perfect straw burial simultaneously

during operation

(modular and easily replaceable). -

Feature 07

Use of auxiliary skids to neatly level

the soil accumulating

at the end of the rotary tiller during operation.

Rotary tiller maintenance inspection and refueling items(AR6000F)

▲ : Check

● : Replace

| Inspection Point | Oil Type | Oil Inspection Time | Volume | Instructions | |||

|---|---|---|---|---|---|---|---|

| Everyday | 50 Hours Everyday |

100 Hours Everyday |

200 Hours Everyday |

||||

| Gearbox | Gear Oil | ▲ | ▲ | ● | 8.0 | Check the oil level using the oil gauge, and replace or add oil as needed. | |

| Side Cover | Gear Oil | ▲ | ▲ | ● | 4.0 | If oil does not flow out when you open the inspection plug, add oil. If oil flows out, check the oil's color and foreign matter condition, and replace the oil if necessary. |

|

| Bearing Cover | Gear Oil | ▲ | ▲ | 0.2 | The oil level is adequate when it reaches the inspection plug. | ||

| Universal Joint | Grease | ▲ | ▲ | Grease Nipple Injection | |||

| Conclusion of Each Part |

▲ | ▲ | Check the attachment status of the top master’s plow blade and the plow shaft. |

||||

| Blade | ▲ | ▲ | Inspect bolts and nuts for any damage or deformation. | ||||

※ After the initial 50 hours of use, replace all areas where gear oil is injected.

※ When replacing oil, dispose of waste at a designated, authorized waste disposal facility.

-

Contact Us

031.8057.9311Our Product Online Quote Inquiry

- Fax. 031-8057-9313

- agros@agros.co.kr

-

Business Hours :

09:00~18:00

Lunch Time :

12:30~13:30

※ Closed on weekends

and public holidays

- Download

- Youtube

- TOP